“Artificial intelligence will digitally disrupt all industries. Don’t be left behind.” ~Dave Waters

Introduction:

The most essential way to ensure that a company’s supply chain work processes are operating at the highest possible level is with a well-oiled logistics team. With the growing digitization of the professional world, more and more companies are adding artificial intelligence(AI) to their supply chain in order to maximize their resources by reducing the time and money spent on figuring out how, where and when to send a package to a certain place.

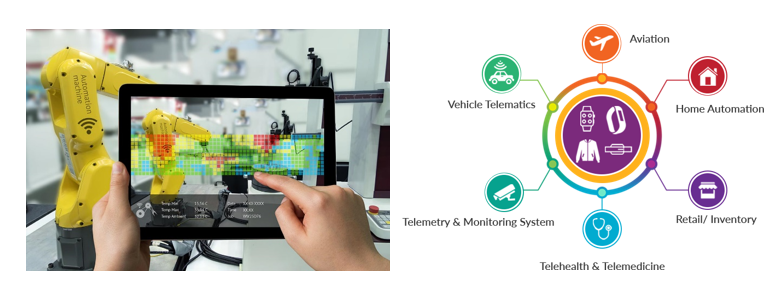

Artificial Intelligence stands to greatly benefit all industries, achieving adoption leaps from consumer segments to enterprises and onward to the industrial sector. Technological progress in the fields of big data, algorithmic development, connectivity, cloud computing and processing power have made the performance, accessibility, and costs of AI more favorable than ever before.

Currently, AI is prevalent inconsumer-facing applications, clerical enterprise functions, online and offlineretail, autonomous mobility, and intelligent manufacturing. Logistics isbeginning its journey to become an AI-driven industry and the recent technological breakthroughs andincreased demands from shippers have pushed businesses to explore AI and thesolutions it can offer to its logistics teams.

Some of the most common solutions that thetechnology can offer in the supply chain are resource management, costreduction through reduced redundancies and risk mitigation, bolsteringtraditional forecasting techniques, speeding up deliveries by optimizingroutes, better customer service and more. With the right intelligent automationbusiness, companies are able to seamlessly update their IT systems and enhancetheir data analysis processes to bolster their logistics processes.

Advantages of Artificial Intelligence in Logistics

1. Load Cost

Predicting the price of a load can be tricky because the cost of shipping varies from season to season, and even from sunshine to rain on a day-to-day basis or by time of the day. AI can help monitor these conditions and choose the right price based on delivery time and what “lane” — route and destination — a shipment is headed. These algorithms monitor a series of parameters such as traffic, weather and socio-economic challenges that help companies reach a fair price that both parties can agree on. Even shipping an item from location 1 to location 2 does not cost the same as shipping an item from location 2 to location 1, even if all other logistical factors are the same due to differing economies and routes from one place to another.

2. Optimizing Inventory

AI also plays a role in the democratization and accessibility of information as the technology can offer a fair price quote to ensure that both parties are getting a fair deal, while also monitoring inventory and load capacity so trucks don’t falter on the execution of the delivery. The technology can also secure and manage the supplier inventory and the number of trucks that are available for delivery. Smart algorithms offer this information ahead of time so clients know the exact price and availability of certain inventory and trucks for a future delivery. AI also offers data analysis to learn which carriers have moved what freight in the past at what price and service level.

3. Tackling Unforeseen Circumstances

Expect the unexpected when it comes to the logistical business as a series of circumstances could affect the expected delivery date of a product. Natural disasters such as hurricanes and floods, carrier bankruptcies and employee strikes can all affect the natural course of a company’s logistical workflow. AI can be trained to learn from contingency plans that can guarantee corrective action in the future in the case of an emergency or a disruption. The technology can re-route trucks to a different distribution center if weather strikes the original distribution center, using information from past disruptions to adapt to changing circumstances.

AI and Machine Learning for Warehouse Management

Warehousing is an integral part of any Logistics Company, and it requires a good understanding of the inventory, demand, supply and challenges in facilitating a smooth transition between the two ends to be successful in the field of logistics.

Machine learning and artificial intelligence come in handy at this juncture, because the planning and management for warehousing depend on the intelligence that can be gathered from the data. The data can analyze vital pointers, including the supply floors like overstocking or understocking, and even the kind of inventory that we are looking at, including the attributes of longevity and susceptibility to damages when in storage.

Autonomous and Self-Driving Vehicles

Self-driven cars are no longer an elementof science fiction. Self-driving vehicles have started to take over theexisting vehicles. The field of logistics and shipping needs this advancementto make a significant impact.

Driverless trucks might be in the nascentstages of development, but the progressive only point towards a positiveconclusion. If driverless trucks are introduced, it can overcome a lot ofhurdles, especially with respect to the mandatory crest that humans require.The laws in most of the countries mandate that drivers can only engage in 11hours of break-free drive. With driverless trucks stepping in, the driving cango on effectively for 24 hours, and it will definitely reduce the cost by atleast 25%.

Conclusion:

The world of logistics and the supplychain is a complicated one that requires a lot of planning, resilience andability to adjust when unforeseen circumstances happen. With the right AIplatform, companies will be able to automate logistics work processes and find alternateroutes for vehicles derailed by road construction or bad weather. Thetechnology can also help to reduce the amount of money and time spentdetermining the logistics of an operation by ensuring that a company’sinventory is replenished and by determining which vehicles are best to carry aparticular load.